|

|

|

|

|

|

| Research leading to these results was funded by the European Union Framework Programme 7 (EU-FP7/2007-2013) Marie Curie postdoctoral fellowship PIEF-GA-2012-327226 (InSiDe-Strain, 2013-2015) | ||

As a part of my outreach activity, my aim is to give an easy-to-follow brief introduction to the research field covered by the InSiDe-Strain project. Although I made an effort to stay scientifically correct, the target group here is the general audience. Hence, for the sake of better understandability by non-experts, I try not to provide deep explanations focusing on special cases and I avoid on purpose any equations that are otherwise not necessary for the understanding of a given term.

For this very reason, the explanations and the glossary may not be handled as a collection of proper definitions but, instead, it is aimed to serve as an explanatory note to the topics and terms that eventually show up in the project's website. Any comments are welcome at ![]()

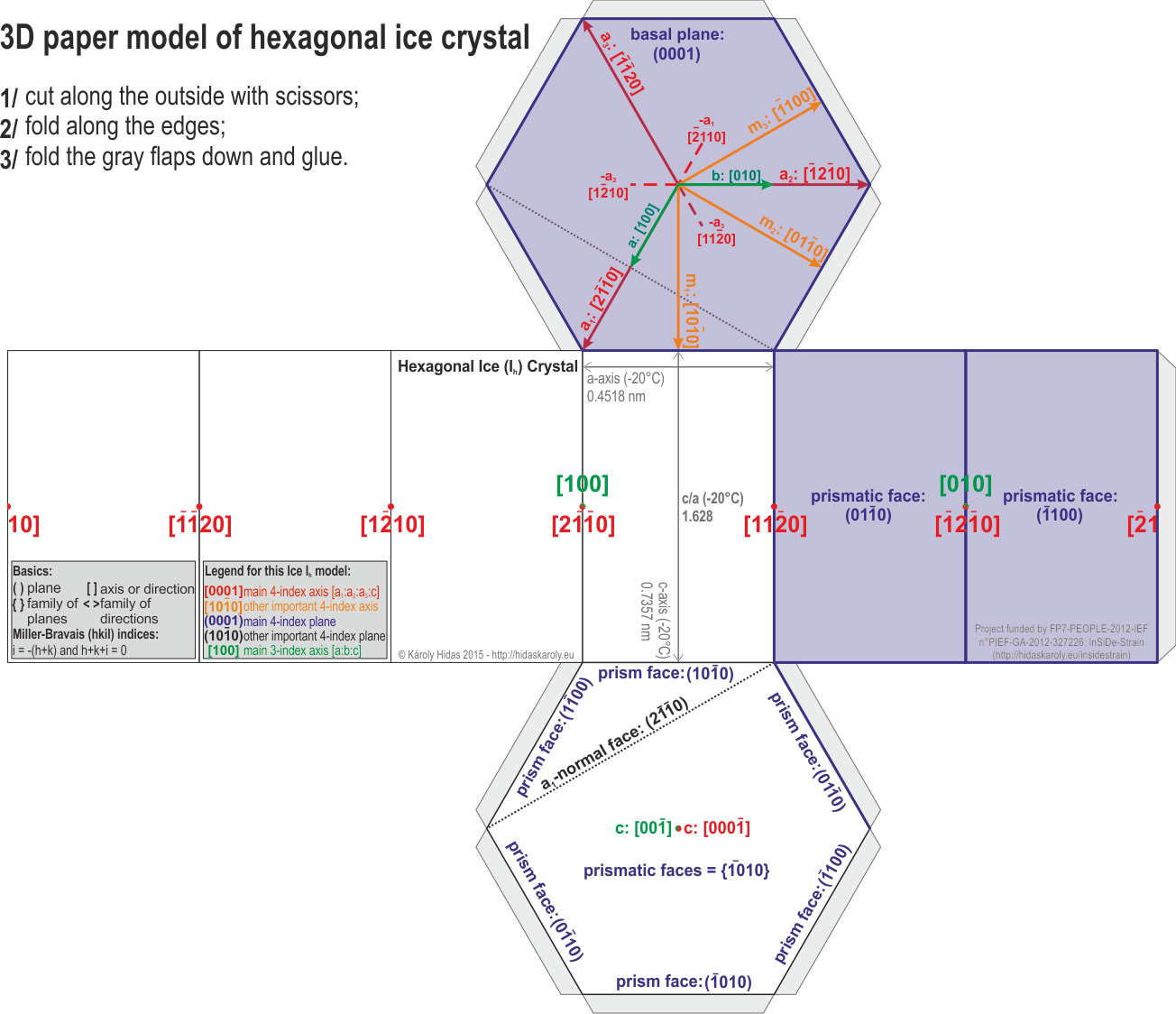

Paper cut-out model of ice with hexagonal crystal symmetry

Do you want to display the hexagonal crystal symmetry in 3D? Build your own ice crystal! Click here to download the annotated paper model then cut out, fold and glue.  |

and if you have not found here what you have searched, then try

| Term | Explanation | |

|---|---|---|

| annealing | process allowing for decrease in the internal energy of the crystals by reorganization of the dislocations or other crystal defects (accumulated during deformation) into configurations of lower energy under static conditions, since this reorganization occurs essentially by solid-state diffusion, it is favored by heating. | |

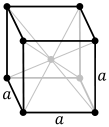

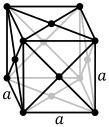

| BCC | body-centered cubic crystal symmetry (e.g., Li, Na, K, Cr, V, W) |

|

| brittle deformation | deformation by fracturing and frictional sliding that results in the loss of cohesion and of continuity of the material | |

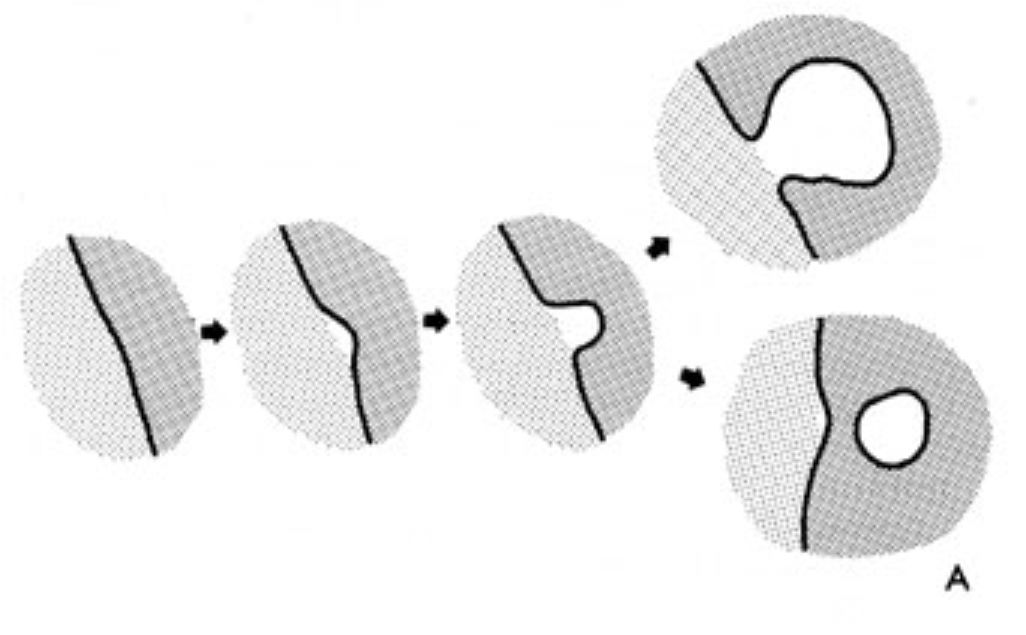

| bulging | creation of new undeformed grains (nucleation) by grain boundary migration |

|

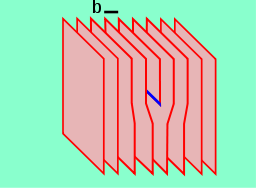

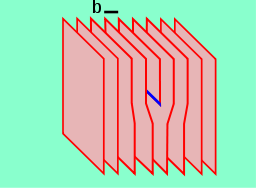

| Burgers vector | the magnitude and direction of lattice distortion introduced by a dislocation to the otherwise perfect crystal lattice | |

| cataclastic flow | brittle deformation involving fracturing of grains and relative movement of the fragments (granular flow) | |

| coaxial deformation | deformation regime in which the orientation of the principal stress and strain axes remains constant through time; pure shear is a coaxial deformation | |

| critical resolved shear stress (CRSS) | a critical threshold value of the applied stress resolved along the slip direction on the slip plane, which is required to promote activation of the slip system in the crystalline structure | |

| crystal plastic deformation | (1) dislocation creep; (2) permanent ductile deformation involving slip and/or twinning that both enable grains to change shape by allowing one part of the crystal to undergo shear with respect to the neighboring parts | |

| Crystal Preferred Orientation (CPO) | statistically representative oriented distribution of crystallographic axes of minerals relative to an external (macroscopic reference frame). The most commonly processes producing CPO is dislocation creep and deformation of crystal mushes, but CPO may also develop by diffusion creep and grain boundary sliding, or by oriented crystallization. | |

| deformation | in this context it is the distortion of a material (strain) due to the application of a force (stress). It is either brittle (material breaks), or ductile (material bends). In a more general definition, deformation includes any processes that result in a change in shape, size or location of a body. | |

| deformation twinning | twinning of crystals as a result of ductile deformation, where crystals will have two parts symmetrically related to each other across a crystallographic plane thus a change of orientation is produced | |

| differential stress | the difference between the maximum and minimum compressive stress acting on the specimen (i.e., grain, mineral or rock) | |

| diffusion creep | change of grain shape by diffusion of chemical components either in aqueous solution (dissolution-precipitation creep) or by solid-state diffusion along grain boundaries (Coble creep) or through crystals (Nabarro-Herring creep) | |

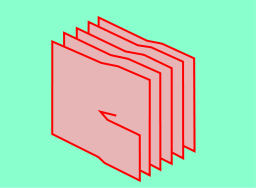

| dislocation | line defect in a crystal, where one row of atom is decoupled from the rest of the lattice; it is the boundary between slipped and unslipped parts of the crystal structure. The two end-members are edge dislocation   |

|

| dislocation climb | motion of dislocations in planes that do not contain their Burgers vector, i.e., movement of edge dislocations out of their slip planes by the addition or loss of point defects and induced by heat | |

| dislocation creep | crystal plastic deformation at high temperature, where deformation of the crystals takes place by the movement of dislocations (dislocation glide) and hardening is avoided by recovery and/or recrystallization processes. | |

| dislocation cross-slip | a process through which screw dislocations move from one slip plane to another in the zone of the Burgers vector | |

| dislocation line | the end of the extra half-space introduced to the crystalline structure by linear crystal defects. See also edge dislocation and screw dislocation. |

|

| dislocation wall | organized array of dislocations in the crystalline structure that forms a subgrain boundary | |

| dissolution-precipitation creep | change of grain shape achieved by diffusion of chemical components in aqueous solution by dissolving material from sites of high normal compressive stress and depositing it at low-stress sites, resulting in a change in shape of the grain or the rock. It tends to predominate at lower temperatures. | |

| ductile deformation | a deformation type that maintains the cohesion of the material subjected to deformation. It is favored at high confining pressure (where rock is less likely to expand, thus break), high temperature (where dislocations may move freely through minerals) and low strain-rates (where dislocations have enough time to move). | |

| dynamic recovery | recovery that occurs during deformation (strain softening) | |

| dynamic recrystallization (DRX) | recrystallization process that takes place during deformation | |

| edge dislocation | an extra half-plane of atoms in the crystalline structure that results in a line defect in the lattice (dislocation line). This line runs along the top of the extra half-plane. If subject to deformation, edge dislocation will move in the crystalline structure parallel to the Burgers vector, that is, perpendicular to the dislocation line. The movement of edge dislocations is best visualized when a hump (edge dislocation) is moved through a carpet (crystalline structure) that is lying on the floor (slip plane).

|

|

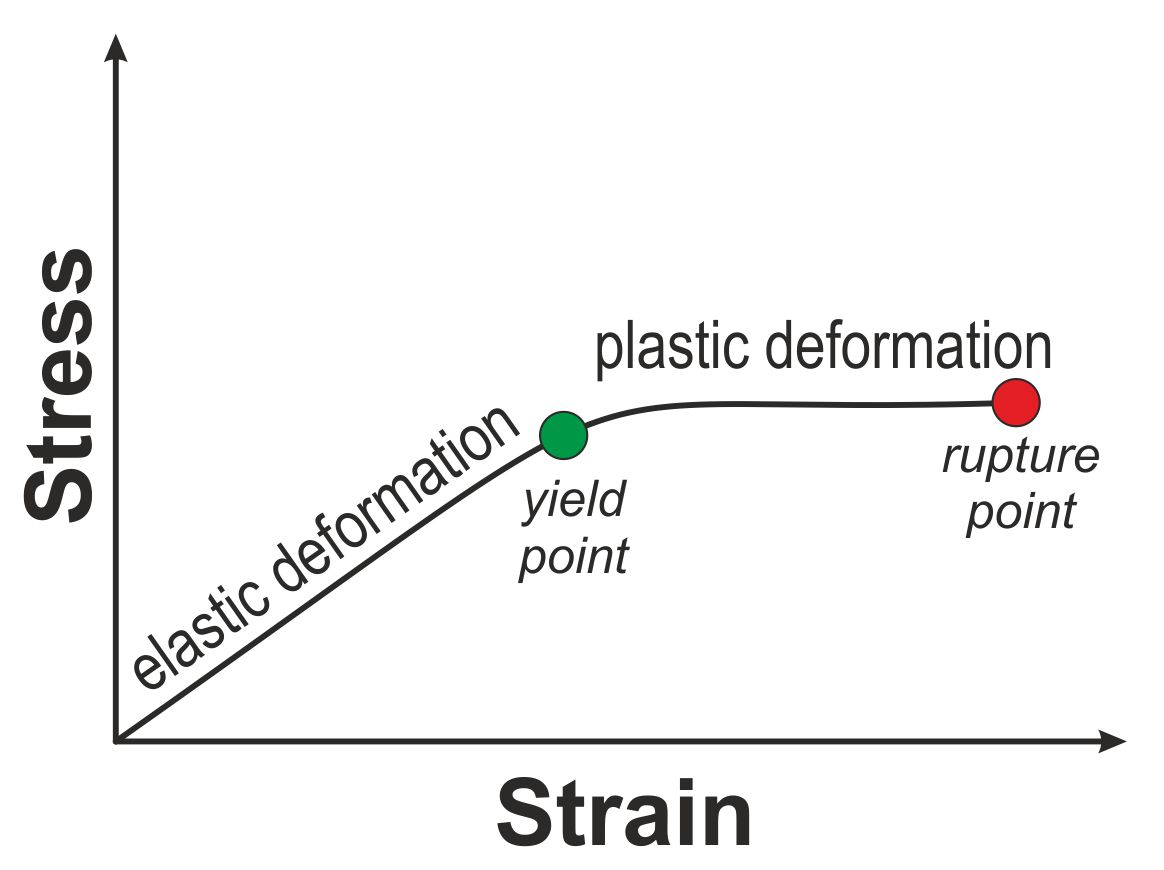

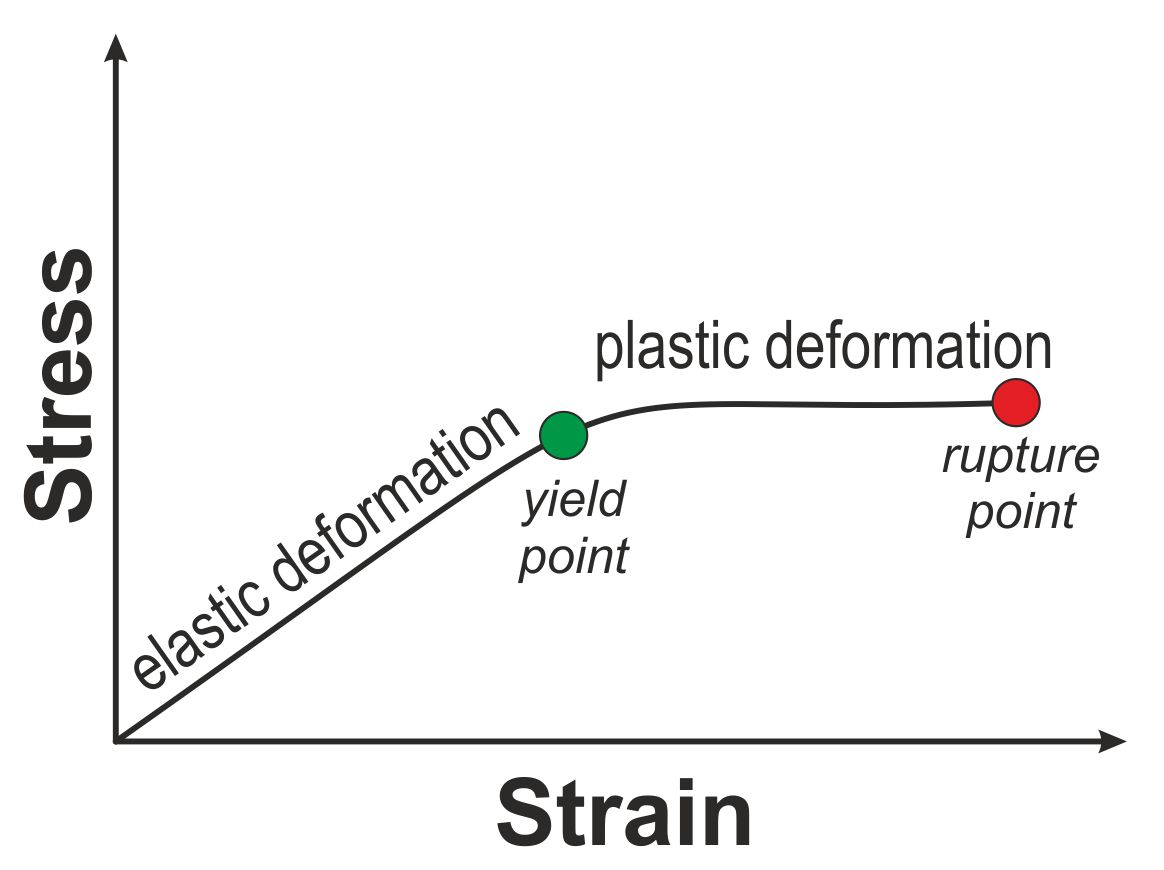

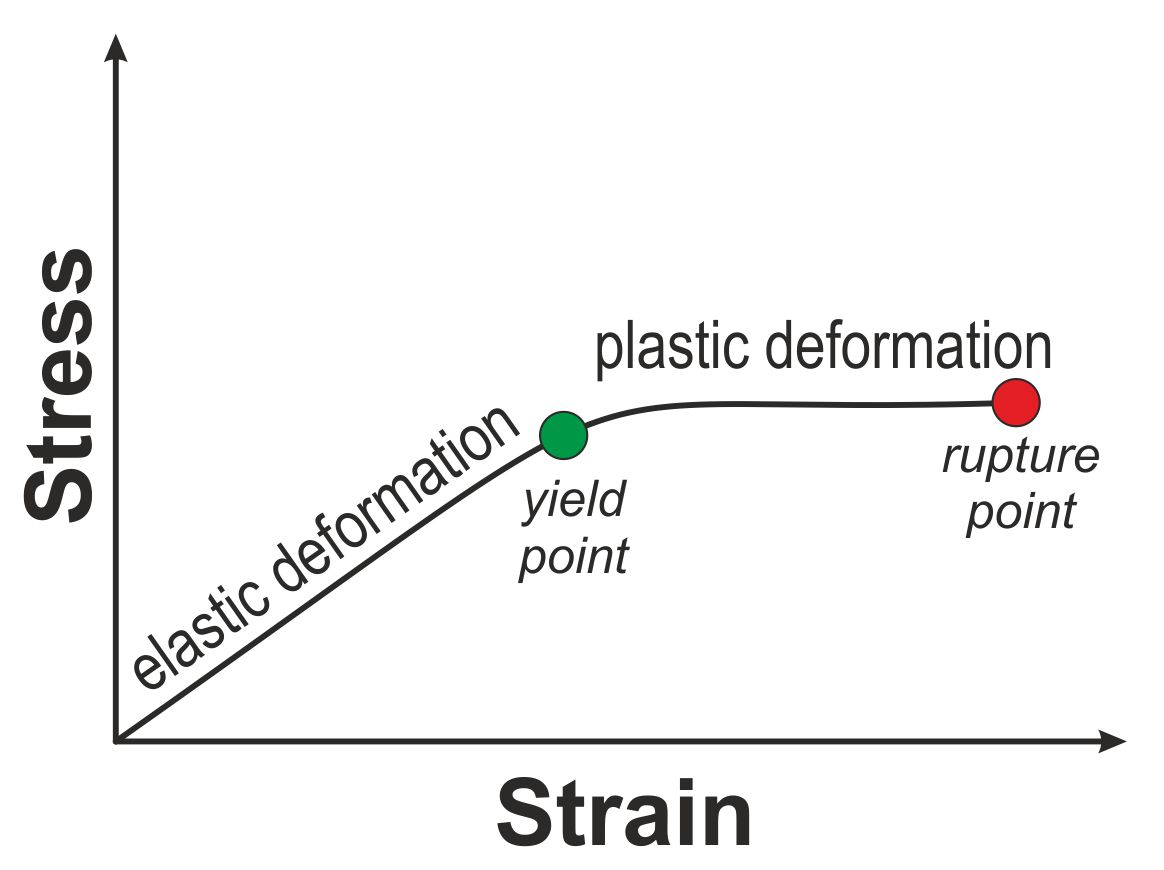

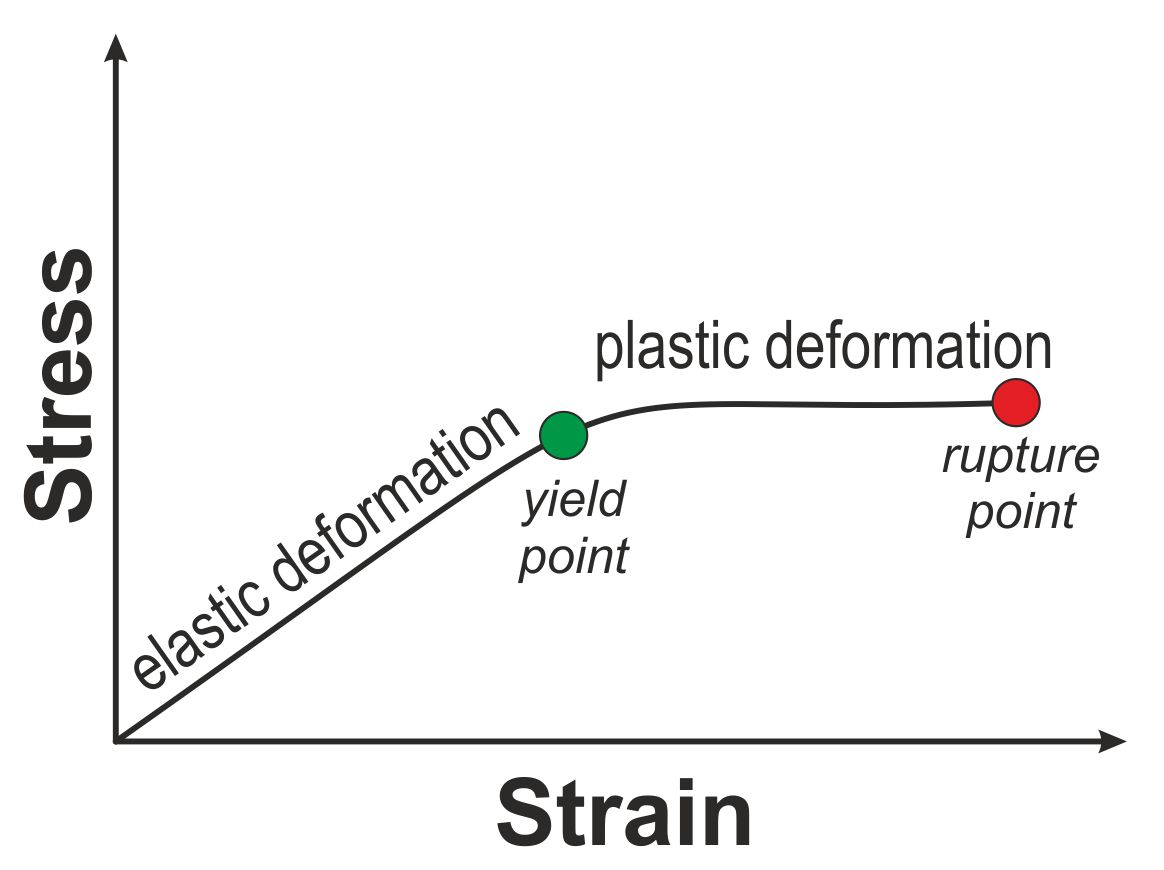

| elastic deformation | a temporary deformation, which is reversible once the forces are removed, allowing the object to return to its original shape. It usually involves stretching of the bonds in the crystalline structure, without slipping of atoms past each other. A spring is an example of a pure elastic material. |

|

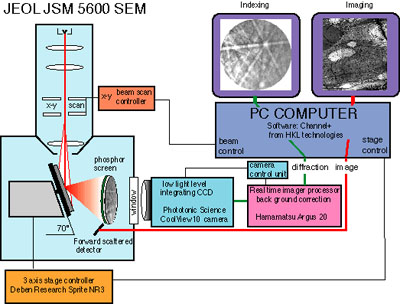

| electron backscatter diffraction (EBSD) | a microstructural and crystallographic analytical technique -usually attached to a scanning electron microscope (SEM)- which is based on the detection of characteristic diffraction of electron beam on the crystalline structure. It provides quantitative microstructural information about the grain boundary, grain size, orientation and phase identity of the sample under the beam. |

|

| extension | applied pulling force | |

| FCC | face centered cubic crystal symmetry (e.g., Al, Cu, Au, Pb, Ni, Ag) |

|

| finite strain | the total strain experienced by the material during deformation | |

| fabric | characteristic configuration of components (e.g. minerals) that compose the rock. In geology it is often interchangeable with texture | |

| flow | in geology this term generally refers to the deformation mechanisms that successfully deform the rocks at the given physical conditions and time in the ductile (or even brittle) deformation regime | |

| foliation | a fabric-forming planar or curviplanar structure in rocks. The term is preferentially used for structures formed by tectonic strain. | |

| friction | the force resisting the relative motion of solid surfaces sliding against each other | |

| grain | an individual unit that is surrounded by grain boundaries in a polycrystalline material | |

| grain boundary | nanometer-wide regions within polycrystals that separate grains and characterized by a specific difference in orientation (high-angle boundary). There is no consensus on the value of the characteristic angular difference in orientation. In rocks, grain boundary is generally taken as a >10°-15° high-angle boundary. | |

| grain-boundary sliding (GBS) | grain-size sensitive deformation mechanism that involves deformation of grains as they slide past each other without loss of cohesion of the material at larger scale | |

| grain-boundary migration (GBM) | movement of a grain boundary in a direction perpendicular to the plane of the boundary. GBM results in growth or shrinkage of grains at the expense of neighboring ones and it plays an important role in recrystallization. | |

| grain coarsening | grain-growth | |

| grain-growth | a process that aims to minimize energy of the system. Grain boundaries are thermodynamically unstable, so a material, after going through recovery and recrystallization (static or dynamic), can still minimize its energy by eliminating grain boundaries that will result in the growth of large grains at the expense of small grains. | |

| grain size-insensitive (GSI) deformation | a group name for deformation mechanisms where intracrystalline deformation (mainly dislocation creep) is dominant; this results in flow laws that do not depend on the grain size. Such deformation regimes are dominant if grain size is large. | |

| grain size-sensitive (GSS) deformation | a group name for deformation mechanisms, which flow laws depend on the grain size, indicating that grain boundaries play an important role on deformation. These deformation mechanisms are dominant if the grain size is small. | |

| granular flow | flow of non-cohesive materials | |

| hardening | increase in the strength of the material with increasing strain, due to accumulation of dislocations, changes in grain size, or in response to reactions | |

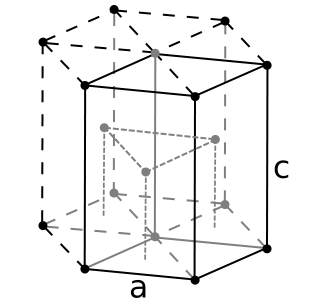

| HCP | hexagonal close packed crystal symmetry (e.g., Mg, Zn, Ti, Cd, Zr) |

|

| high-temperature plasticity | crystal plasticity that is dominated by thermally activated recovery and recrystallization processes, which involve untangling of dislocations immobilized during low-temperature plasticity, eventually leading to the continuity of deformation at a smaller differential stress called as strain softening | |

| intergranular boundary | grain boundary | |

| intragranular boundary | any kind of boundary inside a crystal, such as subgrain boundary, kink-band boundary or deformation twin boundary | |

| kink | a phenomenon that occurs when slip on a single slip plane is inadequate to maintain homogeneous deformation and the grain sharply bends, localizing the deformation into kink bands | |

| kink-band | part of a crystal, where deformation is localized by kinking, which enables shortening of the grain to continue deformation. A kink-band is a part of a grain that undergoes rotation with respect to the unkinked part of the grain, and the axis of this rotation coincides with the line of intersection of the kink band and the slip plane, perpendicular to the slip direction. | |

| lattice preferred orientation (LPO) | crystallographic preferred orientation | |

| lineation | linear elements in a rock. Stretching lineation is used to define a lineation created by elongation of the crystals in response to deformation, it is by definition contained in the plane of foliation. | |

| low-temperature plasticity | crystal plasticity that occurs at less than half the melting temperature at laboratory strain rates and is dominated by glide of dislocations in slip planes, not accompanied by recovery, eventually leading to interference, tangling and immobilization of dislocations; which result in strain hardening | |

| mechanical twinning | deformation twinning | |

| misorientation | angular difference in the orientation between (1) neighboring pixels in an EBSD map (correlated misorientation), or (2) across intergranular or intragranular boundaries in the crystalline structure | |

| Nabarro-Herring creep | change of grain shape achieved by solid-state diffusion of chemical components through crystals | |

| non-coaxial deformation | deformation regime in which the orientation of the principal stress and strain axes rotates through time; simple shear is a non-coaxial deformation | |

| nucleation | formation of new grains of the same mineral during recrystallization | |

| pinning | inhibition of grain growth during deformation due to the presence of second-phase particles | |

| plastic deformation | irrecoverabe or permanent deformation that follows elastic deformation at the yield point |

|

| polygonization | term used for recovery in metallurgy. It refers to the formation of subgrains and not recrystallization (formation of new grains). | |

| pressure solution | dissolution-precipitation creep | |

| pure shear | 2D coaxial strain, which results in elongation in one direction and perpendicular shortening of an object | |

| reaction strengthening | formation of porphyroblasts of strong minerals during a (metamorphic) reaction that makes the reaction product more resistant | |

| reaction weakening | the transformation of stronger minerals to weaker ones and/or their grain size reduction during (metamorphic) reaction, and/or pervasive release of water in dehydration reaction. For example the replacement of feldspar by fine-grained, muscovite-rich aggregates during hydration, which deform more easily than the original feldspar. | |

| recovery | a process that attempt to reduce the concentration and/or tangling of dislocations in a plastically deformed material and to produce volumes of material capable of continued deformation (strain softening) by reorganizing the dislocations without the formation of high-angle boundaries (grain boundaries), so that no new grains appear. | |

| recovery processes | recovery and recrystallization | |

| recrystallization | a process, which forms strain-free volumes in deformed rocks by the creation of new grains of the same mineral (by bulging or subgrain rotation) and/or movement of grain boundaries in solid state. Recrystallization can be dynamic (during deformation), or static (post-dating deformation). | |

| resolved shear stress | the shear component of an applied force projected on a slip plane along the slip direction | |

| rheology | the study of materials’ deformation in response to applied stresses | |

| rupture point | the moment during deformation, when the material loses its cohesion and breaks

|

|

| scanning electron microscope (SEM) | an electron microscope that produces images by scanning the sample with a focused beam of electrons | |

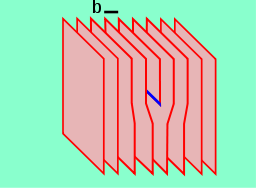

| screw dislocation | linear crystal defect in the crystalline structure, where the dislocation line is oriented parallel to the slip direction. Screw dislocations are best visualized when tearing a piece of paper. It unzips the lattice as it moves through it, creating a screw arrangement of atoms around the core. |

|

| shape preferred orientation (SPO) | a preferred orientation of the elongation or flattening (shape) of the crystals in a rock. It may be formed by deformation in a mush, in the solid-state, or by oriented crystallization. | |

| shear zone | planar high-strain zones in the material, where strain localization occurs | |

| simple shear | rotational non-coaxial strain, which results in shearing of an object | |

| slip | (1) translation gliding that causes layers of a grain to slide past each other without fracturing and without changing the orientation of the slipped portion of the grain; (2) intracrystalline translation glide of a slip system | |

| slip direction | the close-packed direction within the slip plane | |

| slip plane | the plane of greatest atomic density | |

| slip system | depending on the crystal structure, the combination of preferred slip planes and slip direction along which dislocation motion occurs | |

| softening | (1) strain softening, (2) reaction weakening | |

| solution-precipitation creep | dissolution-precipitation creep | |

| solution-transfer | dissolution-precipitation creep | |

| stacking fault | it is an interruption of the periodic sequence of the crystal structure (e.g. a common ABCABC order in an FCC metal may become ABCBC by inserting a stacking fault) and it carries a certain stacking-fault energy | |

| stacking fault energy | the energy carried by stacking faults in a crystal structure. In metals with low value of stacking fault energy dislocation cross-slip are difficult to occur thus the material cannot change its shape solely by dislocation glide during deformation and deformation twinning is likely to occur | |

| static recovery | recovery that occurs after deformation | |

| static recrystallization (SRX) | nucleation and grain growth that occur after deformation if temperatures remain high-enough for grain-boundary migration | |

| steady-state flow | a time or strain-independent deformation, where the stress-strain rate relation remains constant. This suggests that the structure of the material is no longer changing significantly, what during dislocation creep requires activation of recovery or recrystallization processes in addition to dislocation glide. | |

| strain | change in the rock shape during deformation | |

| strain hardening | immobilization of dislocations during crystal plastic deformation as a result of interference and tangling of various dislocations moving along slip planes that cause minerals to increasingly resist strain | |

| strain-induced grain-boundary migration | migration of a grain boundary, a kink-band boundary or deformation-twin boundary by diffusion of atoms controlled by the contrast in internal energy across the boundary | |

| strain localization | a narrow domain in a material undergoing nonhomogeneous deformation where deformation becomes more intense than in its surrounding, leading to the formation of a shear zone. Strain localization is brittle if the material breaks (e.g., faults), or ductile if the cohesion of the material is preserved (e.g., ductile shear zone). | |

| strain rate | the speed of deformation (strain accumulation) | |

| strain softening | unlocking immobilized dislocations by recovery and recrystallization that allow crystals to continue plastic deformation at a smaller differential stress. The formation of a shear zone in a deforming body is usually controlled by softening processes. | |

| strengthening | strain hardening | |

| stress | the force over an area; its unit is in Pa and it is often called as pressure on a boundary/plane. Stress is typically decomposed into components normal and parallel to the boundary (shear). | |

| stress ellipsoid | the product of compressive, or tensile deformation applied to a unit sphere | |

| stress-induced solution-transfer | dissolution-precipitation creep | |

| stretching lineation | lineation formed by deformation | |

| subgrain | relatively strain-free volumes inside a crystal that are divided by subgrain boundaries and have uniform optical and therefore also crystallographic orientation | |

| subgrain boundary | a low-angle (less than the grain boundary; <10° in rocks) array of edge dislocations in the crystal structure that is formed during plastic deformation | |

| subgrain rotation recrystallization | a nucleation method during recrystallization that occurs when dislocations accumulate at subgrain boundaries (dislocation walls) causing the boundaries to progressively increase their misorientation until low-angle subgrain boundaries become high-angle grain boundaries | |

| superplastic deformation | very large strains (up to 1000%) achieved without losing cohesion, as well as without strain localization in very fine-grained (<10 µm), subgrain-free (dislocation-free) aggregates, accomplished mostly by grain-boundary sliding | |

| tension | extension | |

| texture | fabric | |

| vacancy | point defect in the crystalline structure, which forms when an atom is missing from a position that should be otherwise filled in a perfect crystal | |

| von Mises criterion | five independent slip systems are necessary for plastic deformation without fracturing at grain boundaries | |

| weakening | (1) strain softening; (2) weakening of the rocks by reaction | |

| work hardening | strain hardening | |

| work softening | strain softening | |

| yield point | the turning point during ductile deformation, where initial recoverable elastic deformation becomes a permanent plastic deformation |

|

| Zener-pinning | pinning |

|